recent project

Plant Removal & Installation – Kemira Chemicals, Bradford

Project Brief

complex plant removal and installation project.

Butterfield of Skipton (BOS) was recently contracted to carry out a complex plant removal and installation project at Kemira Chemicals in Bradford, working alongside operatives from Meastim.

Our responsibilities included the preparation of all method statements, risk assessments, and detailed lift plans, as well as the selection and hiring of a suitable crane for the project.

Scope of project

What we did…

Removal of Redundant Equipment

Lifting Operations

Strip-Out of Existing Structures

Installation of New Equipment

Reinstallation & Modifications

- Removal of Redundant Equipment:

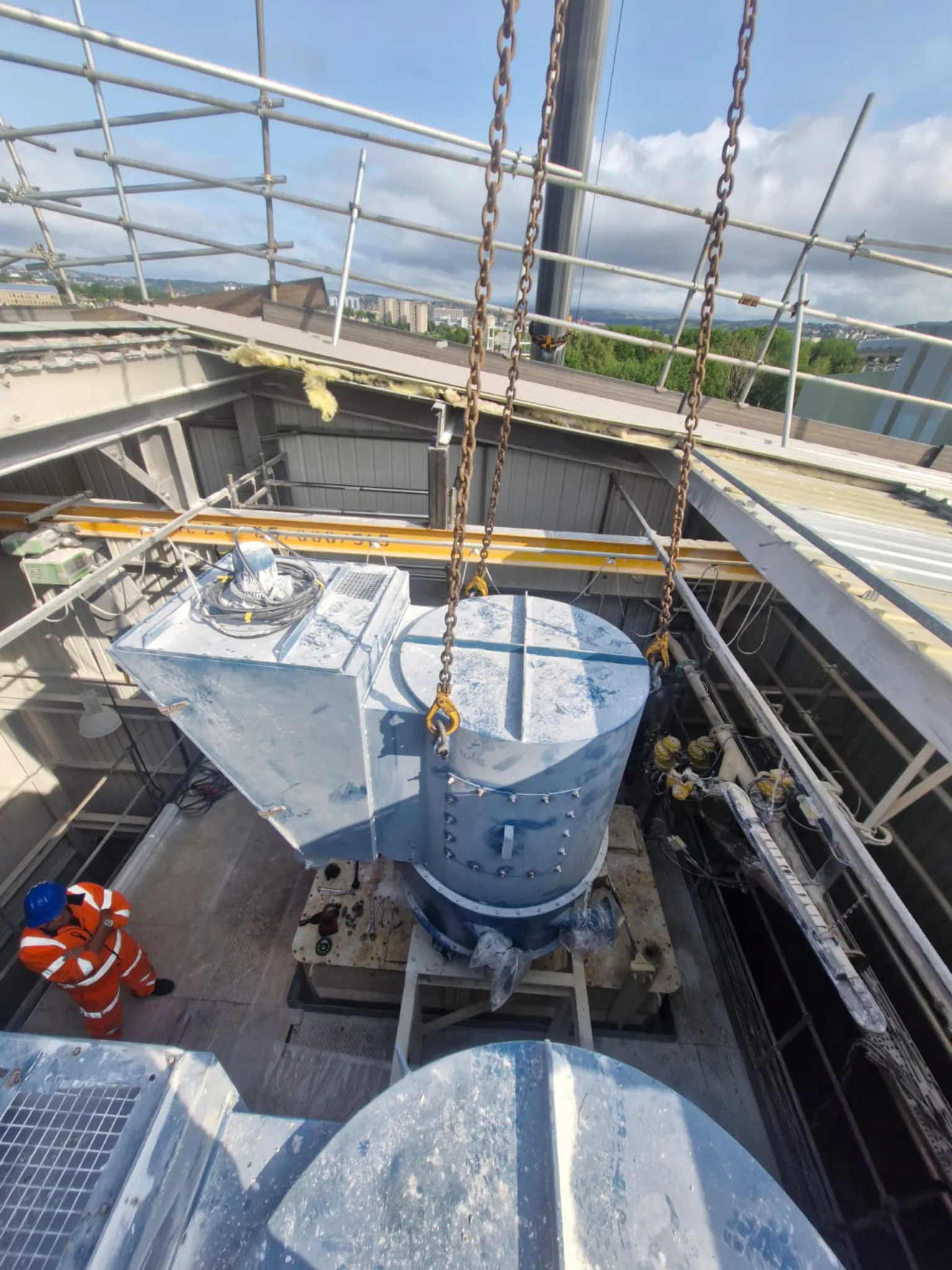

BOS operatives disconnected all associated pipework, removed roof sheets, a structural brace, and altered existing purlins by cutting and splicing them. We also fabricated and welded new support brackets in-situ to maintain structural integrity. - Lifting Operations:

Both the existing blenders and hoppers were carefully lifted out of the building. - The blenders were placed directly onto transport for removal and disposal as scrap.

- The hoppers were temporarily placed onto a scaffold structure on site for servicing, before later being reinstalled.

The lift plan was prepared by a qualified Appointed Person within the company, and all lifting operations were carried out by trained and certified slinger/signallers to ensure safe and efficient execution.

- Strip-Out of Existing Structures:

We removed all surrounding steelwork and walkways, as well as the flooring and steel framework forming the mezzanine around the plant. - Installation of New Equipment:

New blenders were installed. Due to their smaller footprint, BOS fabricated and modified the surrounding mezzanine floor, steelwork, and flooring to suit. - Reinstallation & Modifications:

All walkways, hoppers, and pipework were reinstalled, with modifications made to accommodate the new configuration. The structural brace was reinstated, and the roof was made fully weatherproof.

Challenges Overcome

How we did it…

Weather-Sensitive Environment

Tight Schedule & High Standards

- Weather-Sensitive Environment:

The customer’s process and product could not be exposed to moisture. As such, the roof had to be temporarily removed and reinstalled daily, with a strict requirement that it be made watertight each night. This required careful planning and rapid execution to align with a narrow weather window. - Tight Schedule & High Standards:

All works had to be completed efficiently and to a high standard to minimise downtime and avoid disruption to the client’s operations.

Project Details

Project

Kemira Chemicals

Location

Bradford

Date

June 2025

Partner

Meastim

Structural Steel Experts

Choose Butterfield for your next project!

Call Now